Specialist K Rend Rendering company in Liverpool, Merseyside.

Merseyrend ltd pride ourselves on being a Specialist K rend Rendering team. We are one of the leading k rend rendering companies in Liverpool, Merseyside and the Northwest.

We recommend K Rend FT, or Weber Pral M. Over a high polymer base coat, incorporating an Alkali resistant reinforced mesh. Working to plastic beads. However we are highly flexible and experienced in all the different systems of Rendering. Here is a brief description of a few different systems of render and rendering products Merseyrend ltd use.

We work with all types of external render but we mainly use k rend rendering systems since it is so popular at the moment and everybody wants their homes finished with k rend rendering.

Base coat or Scratch coats are the first coat to be applied . They are used to control the suction of the substrate (background), and to help strengthen the finish coat. Are cement based and can be polymer modified for flexibility, strength and durability. Can be used on unusual substrates where greater flexibility and adhesion is required. Merseyrend ltd choose to use a base coat incorporating an Alkali resistant reinforced mesh, in every job. This allows an even, strong, consistent background as the foundation for every finish.

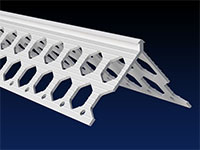

Plastic beads are uniquely rigid and yet resilient. compared to stainless steal or pre galvanised beads. they are ideal for damp, wet or corrosive environments or where plaster drying times may be extended. They come in a wide range of colours to suit which ever colour render you choose.

Monocouche renders and scrapped textured renders are a Silicone based. They only require mixing with clean water on site, they are weather resistant, through coloured which means the colour is contained in a special pigment, which is mixed into the render, so when it is applied to the outside of a building the surface is a rich uniform colour that requires no painting, meaning low maintenance with no decoration required. They are suitable for most types of brick or block. They can also be used as a finish in conjunction with a polymer modified base coat.

Merseyrend ltd choose to use the markets leading two brands, K rend, and Weber. However we are very flexible and can use any product as per clients request.

Pebble dashing is briefly described as a layer of pebbles thrown onto a freshly applied two coat system. The traditional way is to use a two coat sand and cement mortar. The types of pebbles used may be limestone spar, Dorset spar(brown pea shingle), marble chippings . Sizes and colours vary.

The modern system is a Premixed dash receiver. Premixed dash receiver products are available pre-coloured and only require mixing with clean water on site. These products allow uniformed colours and background suction and a mix consistency that cannot be guaranteed using the above sand and cement mixes. They contain silicone and polymer additives to give a stronger bond that is flexible and less likely to crack. There are over 20 different aggregate(pebbles) colours to choose from.

This type of finish is usually carried out in two coats. A rendering scratch coat, then plain finishing coat is trowel applied, ruled, then rubbed up to a flat finish. It is traditionally carried out using sand and cement. The sand must be washed sand (sea sand is unsuitable because of the risk of eforescence due to the presence of salt), and Portland cement, also incorporate a waterproofer to protect the background and regulate the suction for the finishing coat.

This is the cheapest option but comes with disadvantages. Sand and cement doesn't come coloured so requires paint work every few years. Structurally, sand and cement isn't flexible so it is more likely to crack. During summer or winter, temperature changes cause the render to expand and contract suddenly, resulting in cracks. If this happens, water gets into the cracks and soaks into any voids between the render and the substrate.

Sand and cement render requires it to be treated and repainted as a result of cracking occurring so this type of render has a fairly high upkeep. Merseyrend ltd has modified this system with new methods. We use a Polymer modified base coat incorporating the alkali mesh, to make the render more flexible and prevent cracking. Following the same method as a traditional sand and cement system.

Silicone / Acrylic thin coat renders come premixed, are through coloured renders, to reduce maintenance and future over painting. They come in different grain sizes, and a wide range of colours, to suit your taste and design options. They are water repellent and resistant to Algae and Fungi and also have an impact resistant surface. They are to be used with a two coat Polymer base coat incorporating an Alkali mesh.

Merseyrend ltd choose leading manufacturers Wetherby, and K Rend. We have also worked on projects using Sto, Alumasc, and Knauf conn S.

If you require K rend rendering or any other finish done to your property and you live in Liverpool, Merseyside then please give us a call today.